THE OPTIMUM FIBER COLLIMATOR ARRAY

Perfecting the art of fiber collimation with micro-lens arrays from INGENERIC

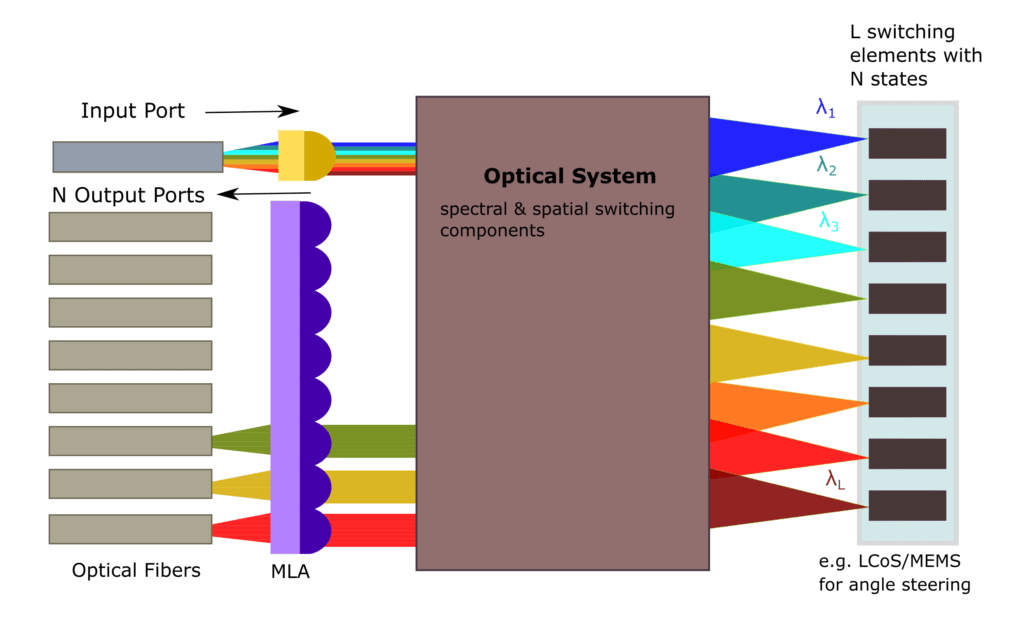

To accommodate the ever-growing demand for precision collimator arrays for optical switching architectures in telecommunication ROADM and hyperscale datacenter networks, INGENERIC has developed one dimensional (1D, 1×16) glass micro-lens array using a highly reproducible and sophisticated precision micro-glass molding process. Since most of our projects affect confidential customized products which are not intended for distribution, the micro-lens arrays we have newly developed serve as demonstrators and can be requested as test samples.

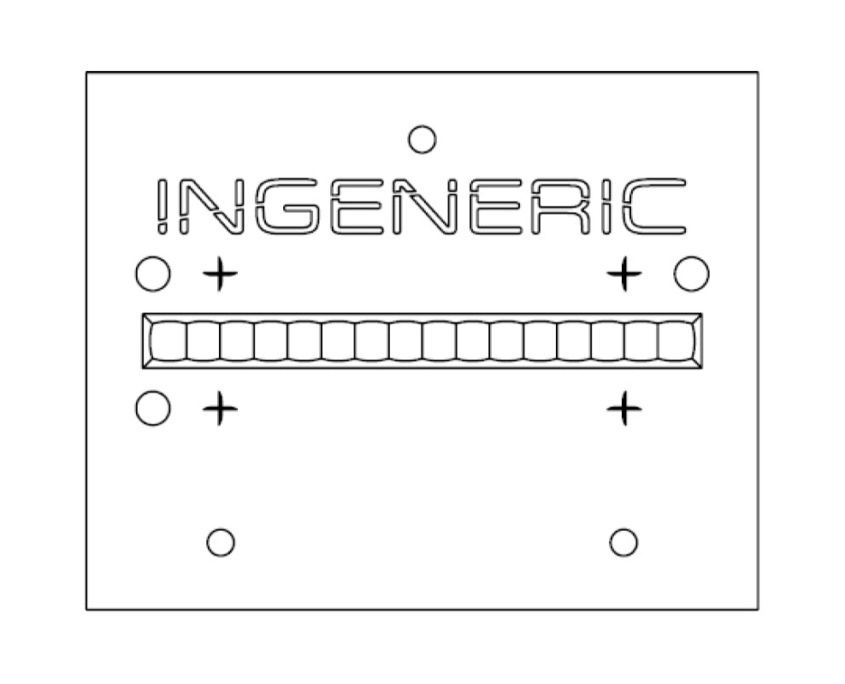

INGENERIC 1D (1×16) plano-convex MLA with

fiducial markings and standoff structures