THE OPTIMUM FIBER COLLIMATOR ARRAY

High-Precision Microlens Arrays for Optical Cross-Connect Switching

Market and solution:

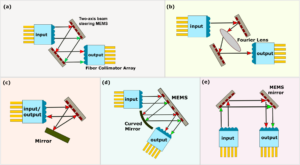

The globally growing internet traffic and the need to store huge amounts of data result in expanding datacenter networks such as hyperscale datacenters. Optical switching technologies form part of telecom and datacom networks where they perform functions like data routing (between servers), wavelength switching, protection, restoration, and fiber management. Optical switching can be seen as the core technology for achieving high bandwidth.

Precise 2D Lens Arrays are core components for high coupling efficiency:

Miniaturization of these optical switches however imposes strict optical and mechanical tolerance demands for the lens arrays. Commercial precision molding offers promising prospects when maximum design accuracy, tight-tolerance manufacturing, and high part-to-part reproducibility are required.

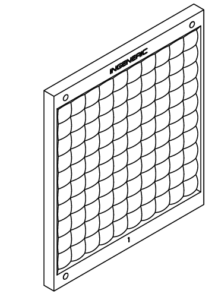

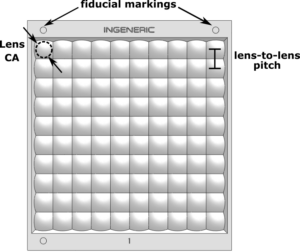

INGENERIC MLA

10×10; 18x16x1.055mm; 1260-1630nm

The used manufacturing technology guarantees highest reproducibility:

We fulfill most challenging series manufacturing demands for custom micro lens arrays with our advanced in-house toolmaking capabilities, years of expertise in glass molding, strict quality control, and continuous upgrading of optical measurement technologies in the micro-domain. That is why we can now introduce our 10×10 plano-convex microlens array developed as a technology demonstrator for the collimation of 2D fiber arrays in free-space, showcasing the many advantages of the technology and give R&D specialists an opportunity to test the MLAs live in optical assemblies.